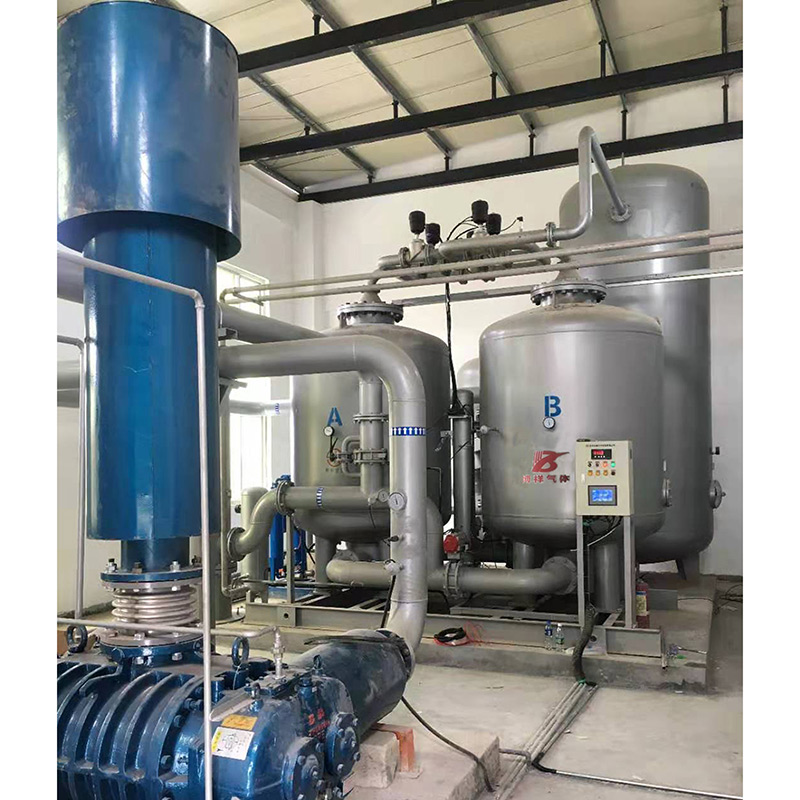

CE Certification Vpsa Oxygen Equipment – VPSA oxygen generating equioment – Boxiang Detail:

Company Profile

according to the parameters given by your company: oxygen maximum flow rate: 150NM3 / h, the purity is: 93%, atmospheric pressure dew point – 55 ℃ or less and nitrogen export pressure: 0.3 MPa (adjustable), exhaust temperature of 40 ℃ or less VPSA oxygen plant, our company in response to put forward the technical requirements of your company at the same time, the energy consumption and the failure rate according to the minimum standards for design, made the following solutions for your reference.

The terms and units used and implemented in this technical plan are in accordance with the relevant standards of the People’s Republic of China.

Hangzhou Boxiang Gas Equipment Co., LTD is responsible for the authenticity and rigor of the technical scheme.

The device is designed according to the indoor installation requirements, and the temperature below 0°C is not considered.

The Buyer shall ensure that the indoor ambient temperature of the unit is maintained above 2°C and below 40°C.

|

atmospheric conditions |

||

| The name of the | unit | Technical Specification |

| altitude | M | +300 |

| The environment temperature | °C | ≤40 |

| Relative humidity | % | ≤90 |

| Atmospheric oxygen content | % | 21 |

| CO2 | ppm | ≤400 |

| dustiness | mg/m3 | ≤200 |

| The cooling water | ||

| The name of the | unit | Technical Specification |

| Inlet temperature | ℃ | ≤30 |

| Inlet pressure | MPa(G) | 0.2~0.4 |

| Power supply conditions: |

Low voltage 380V,50Hz, AC three phase four wire system, neutral direct grounding. |

|

General industrial air should be free of dust, chemical components, carbon monoxide, hydrocarbons and corrosive gases.

dust content: Max. 5mg/m3

SO2: Max. 0.05mg/m3

NOX: Max. 0.05mg/m3

CO2: Max. 400ppm(vol.)

In addition, the total amount of acidic gases such as hydrogen sulfide and hydrogen chloride in the air should be less than 10 parts per million.

Principle of psa air separation to produce oxygen

The main components in the air are nitrogen and oxygen. Therefore, adsorbents with different adsorption selectivity for nitrogen and oxygen can be selected and appropriate technological process can be designed to separate nitrogen and oxygen to produce oxygen.

Both nitrogen and oxygen have quadrupole moments, but nitrogen’s quadrupole moment (0.31 A) is much larger than oxygen’s (0.10 A), so nitrogen has A stronger adsorption capacity on zeolite molecular sieves than oxygen (nitrogen exerts A stronger force with ions on the surface of zeolite).

Therefore, when air passes through the adsorption bed containing zeolite adsorbent under pressure, nitrogen is adsorbed by the zeolite, and oxygen is less absorbed, so it is enriched in the gas phase and flows out of the adsorption bed, making oxygen and nitrogen separate to obtain oxygen.

When the molecular sieve adsorbs nitrogen to near saturation, the air is stopped and the pressure of the adsorption bed is reduced, the nitrogen adsorbed by the molecular sieve can be desorbed out, and the molecular sieve can be regenerated and reused.

Oxygen can be produced continuously by switching between two or more adsorption beds.

The boiling point of argon and oxygen is close to each other, so it is difficult to separate them, and they can be enriched together in the gas phase.

Therefore, the psa oxygen production device usually can only obtain the concentration of 80% ~ 93% oxygen, compared with the concentration of 99.5% or more oxygen in the cryogenic air separation device, also known as oxygen-rich.

Note: 1, the choice of pneumatic valve for Bolei or cover rice valve, the supporting cylinder for the import brand.

2. The control system is indoor. The control cable is connected from the equipment site to the operating room with a distance of less than 100m.

Requirements

1. The pipe connection between each system shall be made by the user according to the site layout.

2. Floor area: The final equipment drawing shall prevail, and can be designed according to the user’s actual position.

3. The main standards and specifications for the design, manufacture and inspection of this equipment project shall be implemented according to the current industry standards in China.

Product detail pictures:

Related Product Guide:

We have now a skilled, performance group to offer excellent support for our consumer. We usually follow the tenet of customer-oriented, details-focused for CE Certification Vpsa Oxygen Equipment – VPSA oxygen generating equioment – Boxiang, The product will supply to all over the world, such as: Boston, Juventus, Portugal, We can meet the various needs of customers at home and abroad. We welcome new and old customers to come to consult & negotiate with us. Your satisfaction is our motivation! Allow us to work together to write a brilliant new chapter!

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.